Please consider this: The Holy Grail of the classic auto enthusiast, the deliquescent, rodent infested Jaguar XK slumped in the barn of some crazy old man who is “gonna fix ‘er up some day…”

The sorriest thing about this particular scenario is that the barn is mine, the car is mine and I am that crazy old man.

Some Day finally came. I was wandering the grounds of Greenfield Village http://www.thehenryford.org during the 2014 Motor Muster, arm and arm with the woman for whom I had been looking-mostly in the wrong places-for the past forty years and finally discovered hiding in an online dating site.

If you’re a Car Nut and find yourself in Southeastern Michigan the third weekend of June go to the Motor Muster. It’s a really big show, autos scattered over the grounds of Greenfield Village, Henry Ford’s collection of historic buildings, worth a visit on its own. The setting is idyllic, relaxing. It’s not all smoking hot and blistering pavement as the Woodward Dream Cruise https://en.wikipedia.org/wiki/Woodward_Dream_Cruise two months later usually is. The cars are grouped by year rather than make so one can get a perspective on what various automakers were offering at the same time.

In the 1938 area of the show there were these little Bantam Roadsters:

Apparently the Great Depression had worked wonders in the area of weight reduction.

But not for everyone. By 1941 other people were fat and happy and needed great big cars to tote themselves and their money around:

By the 1950’s the world was pretty much exhausted from the double whammy of the Great Depression and World War II. Wartime manufacturing had shifted back to producing consumer goods and Americans were content.

The 1950’s area of the car show was heavy on stolid, Eisenhower Era vehicles, beautiful from a perspective of 60 years on, their ponderous, utilitarian demeanor shrouded by a comforting fog of nostalgia. Many of them were sweet, lovely, in a bobby-sox and saddle shoe kind of way. Like Veronica and Betty from an Archie comic book. The automotive equivalents of the kind of nice girl your Mom would wish you to marry.

And then there was this:

And this:

A design risen from the ashes of a country that had recently been bombed to near oblivion, a graceful, racy shape evocative of a British fighter plane blended with the civilized interior appointments one would expect of a country house drawing room.”I have one of these,” I mentioned to Lisa. We had only been together for a year or so and there were things we didn’t know about one another yet.

“No way,” she said, “one of these?” The question has been settled for years: women with good taste like sexy cars.

“Well, yeah and no. The green one is an XK 120 OTS, Open Two Seater. This one is an XK 140 OTS. Mine is a 140 Drop Head Coupe. The main difference is mine is all torn apart.”

“I guess that means you have to get your ass to work and put it back together then, doesn’t it?” She pulled me a bit more tightly to her side. That’s one reason I had been looking for her for forty years…

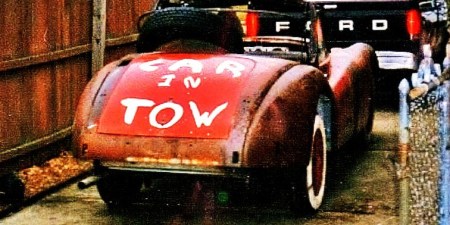

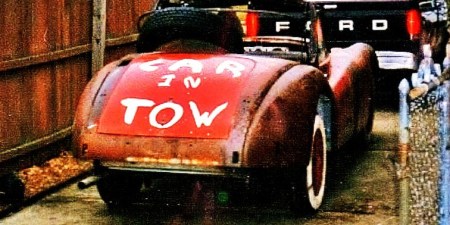

Time to hitch up the old tow bar again…

Maybe I could get away by just replacing the forward cross member. If I could pop it loose, leave the frame rails and steering rack mounts, that might do it:

Maybe I could get away by just replacing the forward cross member. If I could pop it loose, leave the frame rails and steering rack mounts, that might do it:

You must be logged in to post a comment.